Recover E-plastics from demanufacturing

Recover sellable plastics from flat panel display shells.

Validate materials specs for plastic buyers.

Data-rich tracing for material recovery.

Machine Vision Systems To Reclaim Plastics For E-Waste Recyclers

Reclamation Factory’s Plastic Harvester™ systems boost material recovery rates through advanced machine vision, optical sensing and automation. This system integrates with e-waste recycling operations to harvest valuable part-form plastics like TV and monitor enclosures.

Our systems precisely identify, sort, and classify diversion streams to maximize the value of recovered materials, protect downstream equipment, and minimize contamination. Sorts by polymer type, additives, BFR, and other features.

Georgia considers which part form plastics are valuable ABS, PS, PC — and which are contaminated.

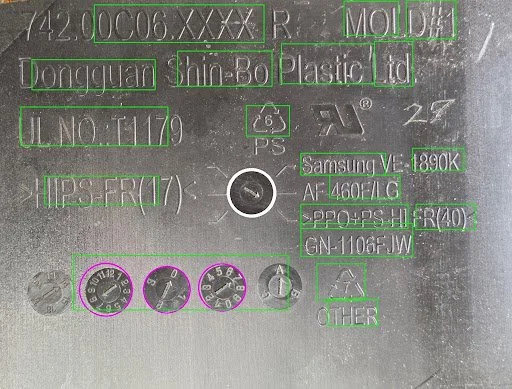

OCR identifier detection results

Text detection(green), resin indicators (white), other indicators (magenta).

-

Choose the right process before you invest in new equipment. We help design and conduct early experimentation to answer the important questions necessary for new system success.

-

We specialize in sorting and classifying part-form plastics quickly and accurately.

-

Fusing image recognition, spectroscopy, and proprietary techniques for rapid classification.

-

We offer site-specific data collection systems for compliance reporting.

-

Optimized for flat panel displays, monitors, other peripheral enclosures. This system observes new parts and learns to recognize and classify components of all kinds.